Since 1973, ISTAM has been collaborating with clients who operate in many different productive sectors by always maintaining high quality standards. Istam also dedicates particular attention to the compliance with deadlines previously set.

ISTAM assists you through the entire production process by guaranteeing innovative consultations and a final product fully aligned with your requests. A perfect product is not only functional and functioning but it is also optimized in terms of costs and time.

No surprises: ISTAM actively works to ensure that its clients always obtain what they ask for thanks to internal competences, a highly qualified team and a cutting-edge consultation method.

Any entrepreneur is well aware how all the aforementioned aspects are essential to reach their goals. For this reason, ISTAM’s clients are always satisfied with the received service and often start long term collaborations with the company.

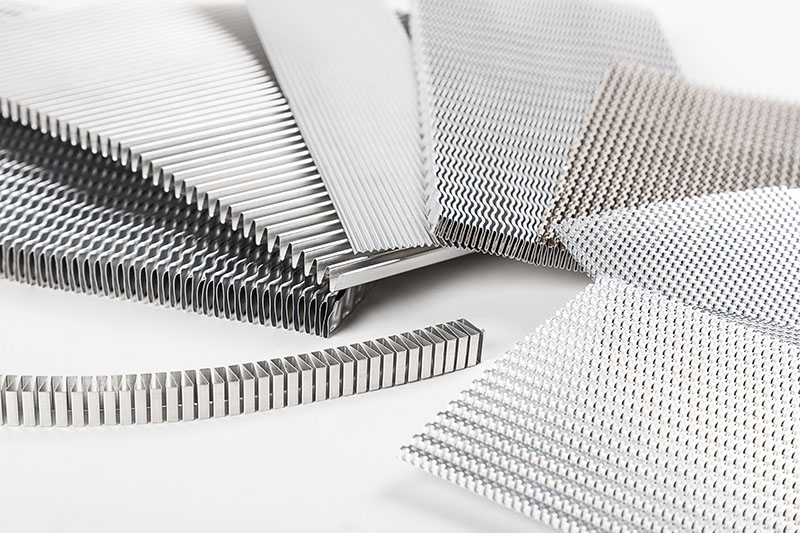

ISTAM produces finned for heat exchangers (FINS), builds and develops aerospace intercoolers (prototypes and/or components), radiators, evaporators of any material (aluminium, steel, copper, brass), perforated tubes of different diameters, covers, brackets of all kinds, connection plates, filter covers, bases and by-pass valves for filtration, deep-drawn, clips and much more.

From consultations to prototyping, from the cold sheet metal forming to aeronautical components production, ISTAM is one of the rings in your chain of success

Prototype Construction and Aeronautical Product Production.

ISTAM produces prototypes and components for the aeronautical industry. From heat exchanger parts to augers, we can offer an excellent service on aeronautical, aerospace and assembled components.

The majority of these components is made with aeronautical quality aluminium, steel or stainless steel. Our multiples options for aerospace components production allow us to satisfy our clients’ needs, providing them with all they ask for, with the maximum precision required by this sector.

Prototype Realisation and Production of Industrial and Agricultural Components.

We handle prototyping and/or the production of industrial and agricultural components, durable and precise.

Our components for agricultural and industrial machines are of high quality thanks to our vast fleet of machinery and our expertise in this sector.

Our agricultural and industrial components are made for a big variety of applications, useful for all necessities, from metal moulds, wire shapes and precision components, to hot-wound, cold-wound and worked springs.

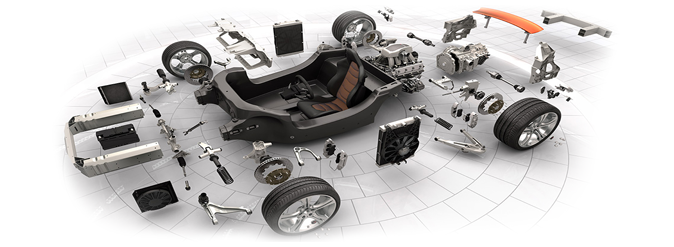

Prototype Creation and Production of Automotive Components.

From decades, ISTAM has been helping its clients of the automotive sector to maintain and monitor the quality of their products and to obtain full trackability on the production line.

We are here to help your company navigate the offered opportunities for the production and prototyping of your automotive components.

With a pros and cons analysis of the various creation techniques, we can help you plan your production. Of course, you will be supported with the necessary certifications which qualify the quality, safety and precision of every single component. Visit the section dedicated to our certifications.

Production of Deep-drawn parts and Deep-drawing Processes.

Deep-Drawing processes are very important in the sheet metal forming sector, by which we aim to obtain many other shapes such as the cylindrical one, the cup one and many more.

Deep-drawn items are very often used in the automotive industry, but are also present is many productive sectors like the industrial sector, agricultural sector, naval sector and much more.

ISTAM creates all deep-drawn of small and medium size (from a 5-10 mm diameter to 400 circa), based on the client’s necessities. If you need a small quantity out of mass production, request a customized quote.

Prototype Creation and Naval Component Production.

ISTAM’s vast expertise has allowed us to develop the skills needed to guarantee a wide range of solutions and manufacturing processes of high quality for the naval sector.

The production of components for the naval sector requires maximum capability for material processing.

Recently, ISTAM has strengthened its services to keep up with this particular sector which demands flexibility and maximum specialisation.

We manage and handle all the aspects of the productive process.

Production of Prototypes.

When it comes to accelerate the development of our new products and the time to market, the validation of a project can be subjected to strong pressure. With a product’s prototype or a component’s prototype, our designers can finally transform their project from a screen into reality.

The mapping pressure of specific characteristics or design elements on prototypes can cause to lose focus on the final product. Our designers are intelligent and their team always act with foresight.

After the prototyping phase and the product’s design process, we always keep a close eye on time, we never lose sight of what the final product is and its performance characteristics. This is because we rely on tested and certified tests.

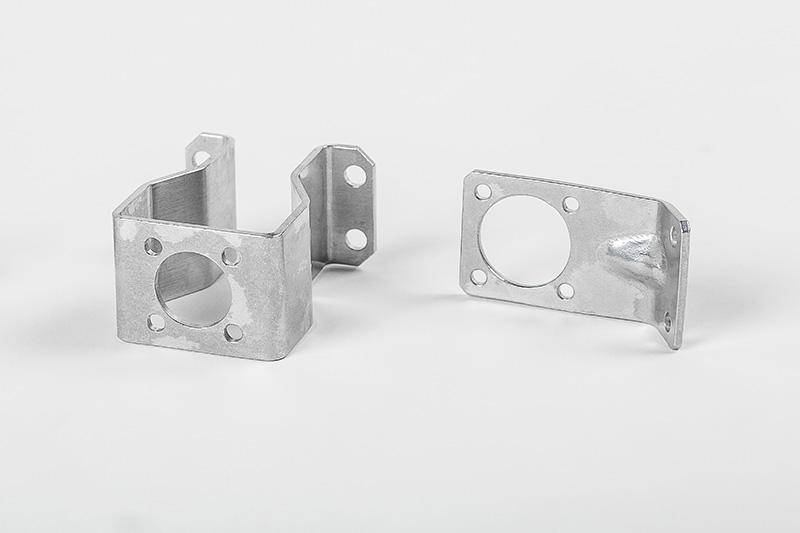

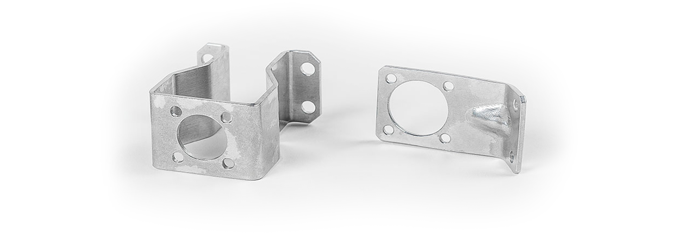

Bracket Creation and Production.

With the term “clamping” we define all those components whose geometry is not round. Therefore, it is easy to guess how many and how various the items achievable are and how many and different the functions feasible by each piece are.

From curtains accessories to components for pressure switches, from generic handles to brackets for lifts, brackets are more or less present in many items of common use.

Bending, rolling, punching, drilling and cutting, brackets require every time the design of a tool more or less complex and expensive. The client has to involve their partner as soon as possible into the development of the product, to avoid further costs.

Creation and Production of Perforated Pipes.

Perforated pipes are hollow pipes whose surface presents various holes. These pipes are often used as components in many sectors such as the automotive, the industrial and the agricultural sectors (for example, in draining systems).

ISTAM has been producing perforated pipes for decades and uses cutting-edge welding techniques to assure you a product of extremely high quality and precision.

Thanks to our production capacity of 1,200,000 pieces per day, we are able to satisfy the production needs of every client in every sector.

3D printing and 3D component printing.

3D printing processes highly differ from conventional production processes, also from a conceptual point of view.

While manufacturing processes (for example, turning, milling, drilling) are subtractive processes of production, 3D printing is an additive production process. Subtracting production processes remove the material from a semi-finished product until the desired size and shape is achieved. Additive production processes directly produce the component of the desired size so there is no need to use semi-finished products or to remove further material.

We handle the design, prototyping and 3D printing of your customized components. In particular, 3D printing is very useful for the production of components in small batches.